Cartonization Process

The cartonization algorithm Oracle Warehouse Management uses minimizes the number of containers used at each level in the packaging hierarchy, subject to volume, weight, and minimum percent fill settings of the containers. The algorithm also verifies the dimensions of the packed material can fit inside the dimensions of the container.

If you defined multi-level hierarchy after all the material is packed at the first level, the algorithm repeats itself with the new containers. The process continues until the top of the packaging hierarchy has been reached, the packaging process has completed the indicated number of levels, or no additional containers are available due to minimum

percent fill, dimensions, or other physical attributes.

The following two examples illustrate how cartonization works on a single and a multiple level cartonization hierarchy. Although labels are generated at all levels in the cartonization process, LPNs are only created for the outermost level for each request.

Single Level Cartonization

Single level packaging hierarchies are most commonly used during sales order pick release for Pick by Label functionality, or to select the right packing container. You may also use it for packing material in inventory and generating labels prior to manufacturing completion if the labeling requirements are simple.

Steps

1. Define an item and assigned contained category group. Define a container and assign the container category.

2. Create a SO and Run pick release with Auto Confirm – No, Create Delivery – Yes, Auto Allocation – Yes, Plan task – Yes.

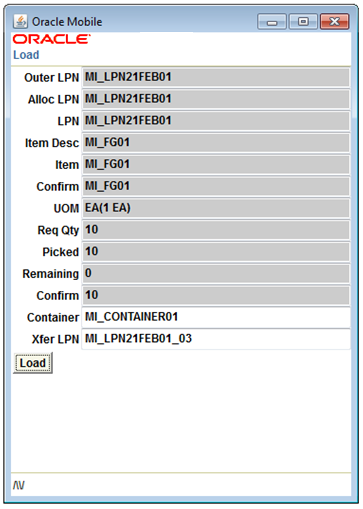

3. Navigate to Load

Enter the pick id (transaction number on warehouse control board)

4. System‘ll show the container number as per the setup.

Multi Level Cartonization

Use multi level packaging hierarchies when you require labeling for more complex packaging configurations, such as when you need to pack inner boxes into outer boxes, that are placed on a pallet. The multiple levels can be packed all at once, or when using the mobile Bulk Pack page, can be broken up into several intermediate steps. Labels can be generated for each of the many levels of the hierarchy.

Packaging vs. LPN

Only the outermost level created at each level of cartonization is defined as a license plate. License plates are not generated for intermediate levels. You can only calculate material availability at the innermost license plate level, and the rules engine cannot allocate nested LPNs and you cannot pick them in a single transaction. The way you

create license plates and packaging entities impacts how labels print and on-hand balance maintenance.

Content and Summary Labels

Labels generate for each level in the packaging hierarchy regardless of whether you create a license plate or record the level as packaging.

LPN Summary labels are printed at every level during the cartonization process. These multi-record labels include all the items contained at or below the current cartonization.

LPN Content labels print at every level that contains loose material. For levels that license plates are not generated, the innermost packaging level contains loose material and a LPN Content label may be printed. Because material availability calculations do not have visibility to packaging levels that do not have license plates, the system also

prints an LPN Content label for the innermost license plate even if there are other levels of packaging inside the license plate.

You can identify all levels created by cartonization with a unique number. If a license plate exists, the number is the license plate number. If a license plate does not exist, the number is a packaging identifier that can be included on the label. You can print the identifier (packaging or LPN), as well as the immediate parent of the level on every

content and summary label. Thus an LPN Summary label may be identified by a package ID and a parent license plate number, or by a license plate number and a parent package identifier. These relationships help you pack the material as determined by the defined packaging hierarchies.

Cartonization - Customer Algorithm

Hi, Can you please let me know the steps in creating Customer Algorithm for Cartonization; and when and how the algorithm behind this will suggest the carton? Thanks, Gowri